LOAD SECURING FOR TIMBER TRANSPORT AND TIMBER STORAGE

Anyone working in the timber industry knows that correct load securing for logs, raw wood, timber and clamping plates during transport and storage is only possible with the right supplies. Timber load securing is ideally done using tear-resistant banding, chains or, if there are sharp edges, also with edge protection. The timber is either secured on pallets or lashed together into bundles so that nothing slips, falls over, rolls back and forth, or falls down, even during emergency braking or sudden swerving. It must be noted, during load securing of timber for transport, that timber “warps” or shrinks as a raw material. The truck driver may therefore need to lash the timber again shortly before transport.

COMPLETE LOAD SECURING IN ONE PLACE

Timber is a heavy, bulky raw material which is susceptible to weathering. Responsible timber load securing is therefore a top priority in the timber industry as well as in the forestry sector. Basic safety aspects which should precede any timber load securing are set out below.

CHECK 1: WHAT TOOLS DO I NEED FOR TIMBER LOAD SECURING?

- Are load securing materials such as banding, lashing straps and chains available?

- Are these materials intact?

- Are additional load securing aids such as anti-slip mats, edge protectors, nets, tarpaulins, loading frames, square sections of timber, wedges, etc. available?

- Are there fixed boxes for small tools and required materials?

- Are there any fixtures for transporting shovels, brooms, pickaxes, etc.?

CHECK 2: HAVE I THOUGHT OF EVERYTHING FOR LOAD SECURING FOR MY TIMBER TRANSPORT?

- Is the load secured against slipping even in the event of sudden changes of direction and emergency braking?

- Have the correct lashing straps and aids been chosen?

- Was the preload force of the lashing straps/chains correctly determined?

- Are individual sticks, machined timber, logs transported in packs?

- Is the maximum vehicle load in terms of length and width taken into account?

SECURE TIMBER TRANSPORTATION – ADVANTAGES OF TIMBER LOAD SECURING WITH SANDER BANDING AND EDGE PROTECTION

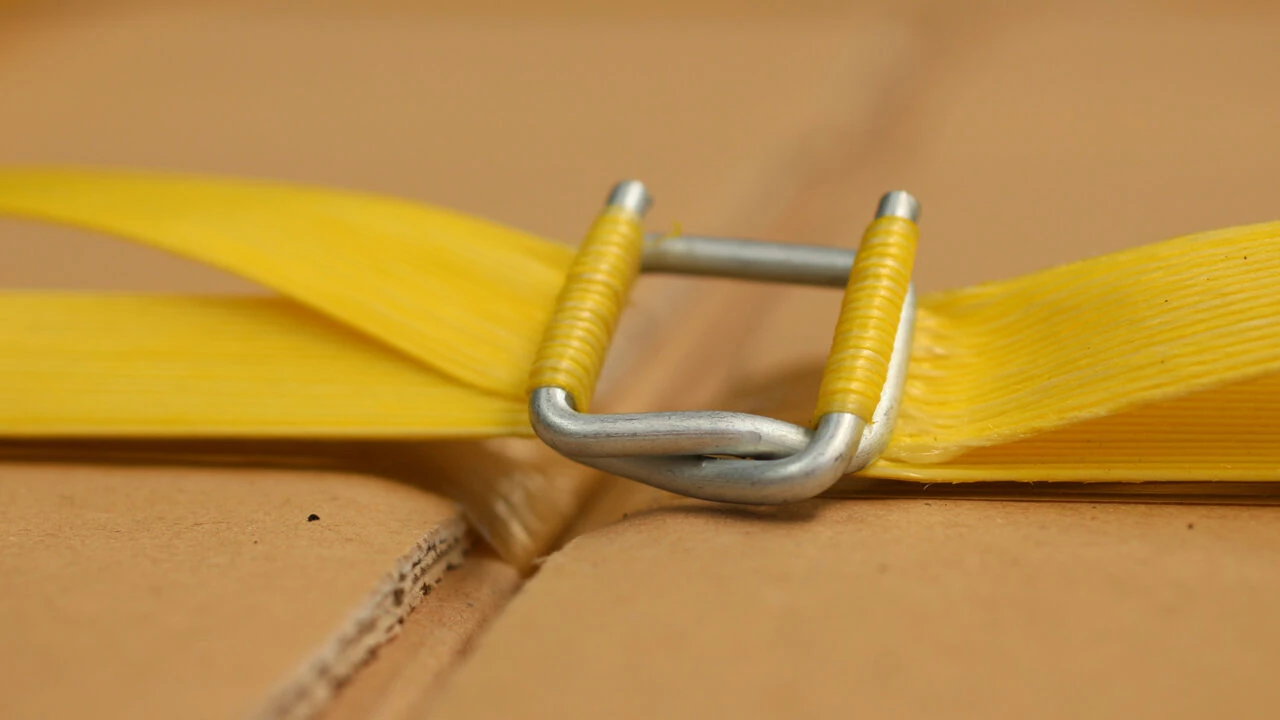

- Sanderband® is the alternative for all load securing where steel bands, wires, cables, chains and straps are otherwise used.

- With strengths of up to 5,000 daN/5,000 kp, Sanderband® is absolutely tear-resistant polyester banding.

- Sanderband® can be retensioned and is therefore particularly suitable for goods such as timber which shrink.

- Sanderband® is resistant to all weather conditions.

- Sander banding is used for bundling logs and raw wood as well as for protecting machined, palletised goods.

- Sharp edges are protected close-fitting Sander edge protection.

- Sander edge protection prevents the banding from being cut into.

- Wooden planks, beams, battens and staple timber goods of any kind are safely stacked with Sander edge protection.

- The timber load securing with Sander edge protection ensures that impacts are absorbed and the packs cannot slip.

- Time is saved when loading and unloading goods which are cleanly palletised using edge protection in comparison to consignments which are packed loose.

MORE INFORMATION ABOUT LOAD SECURING

- For the latest about load securing, see:

www.verkehrsrundschau.de - You can access free loading recommendations for transport of logs using longitudinal loading or short timber using transverse loading:

https://www.bgl-ev.de/web/mensch_umwelt_verkehr/verkehrssicherheit/laden_und_sichern11.htm - Dates for load securing seminars, addresses of regional contact partners for individual consultation and training:

www.svg.de